Leathercraft Site Leather Working Videos

Things you will find here on the leathercraft site

-

Leather Tooling and Carving Videos

-

Knife Sheath Making Videos

-

Guitar Strap Making

-

How to Sharpen Leather Tools

-

Leather Sewing Machine Tutorials

Quick Leather Carving Tutorial

Leather carving is a fascinating craft that allows you to unleash your creative side. With the right tools and techniques, you can transform a simple piece of leather into a work of art. From intricate designs to bold motifs, leather carving offers endless possibilities for expression. Whether you’re a beginner or an experienced artisan, mastering the art of leather carving will open up a whole new world of creativity.

Beveling Leather

Beveling leather is essential for achieving clean, polished edges in your leather stamping projects. To quickly and smoothly bevel leather, start by selecting a beveling tool ( I like and Use Craftool B802 and B803) that suits your project’s needs. Then, hold the tool at a slight angle and apply consistent light taps as you run it along the edge of the leather.

Bruce Cheaney tooling and carving leather video tutorials will help you with your leathercraft journey.

The beveling process enhances the overall look and durability of your leatherwork, adding a professional touch to your craft. Try this beveling technique in your next leather stamping for impressive results.

How to Bevel Leather Quickly and Smooth Short Tutorial

Just a few good leather tooling and carving tools is all you need to get started making your own hand carved and tooled designs. It just takes practice to hone your skills in the leather carving world.

- I use Barry King Swivel Knives

- My Bevelers are made by Craftool

- I use Maul Master and Barry King Mauls

How to Start Leather Carving Quickly. Just get your swivel knife sharp get a 1 1/2″ belt blank wet and cased and let the creative juices flow as you freestyle carve you designs. Practice and explore with your leather carving creativity.

Leather working videos in the leather shop with Bruce Cheaney. 🔔 Please Subscribe!

✔👉 youtube.com/cheaneysaddles Thanks for watching my YouTube videos you are welcome to like, subscribe and share my videos.

How to Start Leather Carving Quickly

#leathercraft

#leather

#carving

#shorts

Leathercraft!! Favorite Leather Carving Swivel Knife – leathercraft How to cut in designs Practice. Practice and Explore. Wet and case your leather and carve your freestyle designs for fun and practice. swivel knife advice by Bruce Cheaney leathercraft.

Beveling leather is essential for achieving clean, polished edges in your leather stamping projects. To quickly and smoothly bevel leather, start by selecting a beveling tool that suits your project’s needs. Then, hold the tool at a slight angle and apply consistent pressure as you run it along the edge of the leather.

The beveling process enhances the overall look and durability of your leatherwork, adding a professional touch to your craft. Try this beveling technique in your next leather stamping tutorial for impressive results.

Carving a Flower into Leather Short and Quick. YouTube #shorts – Whether you’re a beginner or an experienced artisan, mastering the art of leather carving will open up a whole new world of creativity.

Carving leather is a fascinating craft that allows you to unleash your creative side. With the right tools and techniques, you can transform a simple piece of leather into a work of art. From intricate designs to bold motifs, leather carving offers endless possibilities for expression.

Best Leather Beveling Technique – Leathercraft Stamping Tutorial.

Leathercraft Site

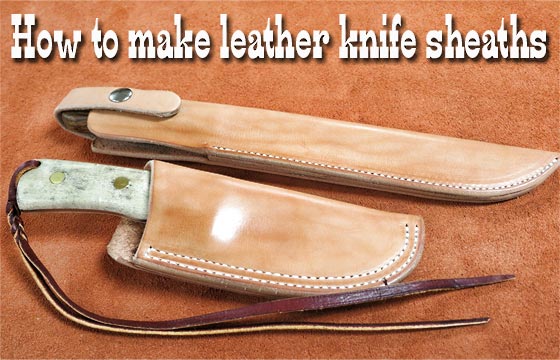

Knife sheaths How to make leather sheath with leather working tools

Article and DIY Videos by Bruce Cheaney

This leather working tutorial will give you some insight on making knife sheaths quickly and efficiently.

Be sure and watch part two when I sew the knife sheath on my cowboy harness stitcher sewing machine.

How to make knife sheaths – Part 2 – DIY Videos – Knife sheath making. Sewing custom leather knife sheaths on a cowboy harness stitcher sewing machine through multiple layers of vegetable tanned leather.

This knife sheath making tutorial is Part 2

I show you how easily and efficiently you can sew your handmade leather knife sheath on a modern day harness stitcher sewing machine.

Once the sheaths have been sewn I show you how to trim the excess off of the bottom layer of leather and then edge the leather with my C.S. Osborne style number 133 western edgers sizes 1 and 2.

Also covered in the knife sheath making tutorial I show you how use a copper rivet to attach a latch strap over the sheath for the fillet knife sheath then set the snap using my Craftool snap setter for Line 24 snaps.

How to make a custom leather knife sheath DIY Videos by Bruce Cheaney leathercraft and leather working instructor find more on YouTube

This post is a three part series on the subject of guitar strap making all on the same page for your convenience.

The leather I am using is from Tandy Leather in Fort Worth Texas and at the bottom of this page I will have the contact information you will need to order your leather and supplies.

I find that the Oak-Leaf leather number 9157-58 works good for tooling and carving designs deep into the leather to make a good looking guitar strap.

To line your guitar strap a 2 to 3 ounce smooth grain leather will work really good and give your strap a custom feel and look.

Guitar Strap Making

Video One

Title- Guitar Strap Making Leather – Vegetable Tanned Leather – Veg Tan – Leathercraft Tutorial

Below is the text that goes with this guitar strap making video tutorial.

Guitar Strap Making Leather – Vegetable Tanned Leather – Veg Tan – Leathercraft Tutorial. DIY leathercraft learn How to make your own custom leather guitar strap. Leather supplies are very important to the leather worker and in this YouTube video I show you a leather I really like for making my hand tooled leather guitar straps.

Guitar Strap Making How to Antique Finish Custom Leather Guitar Straps.

Guitar Strap Making Video Two

Title – Guitar Strap Making How to Antique Finish Custom Leather Guitar Straps Tutorial

Text below goes with the antiquing tutorial.

This is a custom made leather guitar strap that I am antiquing I have allowed three coats of resist to dry so the strap will turn out the shade I like.

It is a good Idea to practice with your antique finish on a piece of scrap leather to understand how this antique process works. You may find that if your resist layer is to light the antique may be to dark for you.

I have plenty of sheep skin pieces cut and trimmed for this process as you can see in the video so I can remove and buff the guitar strap to get the desired look I want.

The third video in this series shows you how I groove my guitar strap with a C.S. Osborne scratch compass. The purpose of a stitch groove is to make a channel that the stitch can set down into to prevent the stitch from wearing out as well as it looks better than not having a groove.

Guitar Strap – How to Make Leather Guitar Straps – Sewing Leather – Custom Leather Working. DIY Guitar strap making tutorial learn to make your own custom leather guitar straps.

The guitar strap making video tutorial below shows you how to prepare your guitar strap so it can be sewn on a leather sewing machine.

Guitar Strap Making Video Three

Title – Guitar Strap – How to Make Leather Guitar Straps – Sewing Leather – Custom Leather Working

The leather and the guitar strap making supplies I used to make this guitar strap came from Tandy Leather in Fort Worth, Texas and North of Fort Worth in Watauga, Texas.

You are welcome to subscribe to my Bruce Cheaney cheaneysaddles YouTube Channel.

Article and Videos by

Bruce Cheaney

Gainesville Texas USA

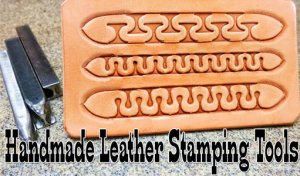

Handmade leather stamping tools create your own unique designs to be different and have your own leather tools made to your liking.

A quick summary of how I made the Serpentine leather stamping tools. First I drew several designs onto heavy poster board and then gently cut the pattern shape out with a leather craftsman knife with a new curved blade so the pattern would be crisp and clean.

Then I went over to my Bit and Spur Making shop and dug around for some steel and found some Hot Rolled 3/8″ x 3/8″ and some 1/2″ x 1/2″ stock and cut my blanks out at 4 3/8″ in length overall for each tool. I used an abrasive cut off wheel to make a clean and straight cut.

Next step in making my Serpentine leather stamping tools was to use some blue layout dye on the end of the metal so I could scribe my pattern onto the end of the tool.

Now it is time to shape the tool shape on the end and I use an abrasive cutoff wheel and a special setup I have mounted on a Baldor number 114 buffer motor… You can use what you have are even a Dremel tool should work. It is possible to make these tools with round and triangle files that you can pick up at the hardware store just takes a little bit longer that’s all.

After I had the tool shaped ground and filed to the shape I was wanting I just simply sanded the end of the tool smooth and then lightly polished the face and that was it. And you see the finished leather stamping tools here in this leather stamping tutorial.

The tools I used are a buffer and a belt sander and hand files. A good resource for metal working tools materials and supplies is Jantz Knifemaking Supply in Davis Oklahoma. Find them online at knifemaking or call and ask for a supply catalog you will be surprised at the content in this catalog that you can used in the leathercraft shop.

Serpentine leather stamping tools

Article and Video by Bruce Cheaney

Gainesville Texas USA

Leather sewing machine. Sewing leather belts, saddles, knife sheaths and holsters with the Cowboy CB-4500.

Leather sewing machine. Lets take a look at what this leather sewing machine can sew and stitch first a leather belt single ply around 10 ounces thick then the next item is a piece of suede leather glued to a piece of closed cell foam rubber a mock up of a piece I sewed for a saddle seat and the next pieces you see in this sewing machine review are saddle parts a flank cinch and flank straps double in thickness saddle skirting 13/15 ounce on top and 10 ounce latigo lining.

I like to use white polyester thread and numbers 200 and 230 sewing machine needles. This machine will sew with much lighter thread if that’s what you want and like perhaps size 277 and a 180 sewing needle.

I have sewn many types of materials on this leather sewing machine like Nylon and Cordura Kevlar including backpacks and tow straps.

Leather sewing machine

There are two options for sewing guides one is the drop down guide like the one I have and the other is a guide that screws to the plate on the bottom by the walking foot and needle.

The Servo motor is a real neat thing that allows you to sew your leather a your own pace and as slow as you would like.

Article and Video by

Bruce Cheaney

Gainesville Texas USA

Leathercraft Site

You are welcome to subscribe to my Bruce Cheaney YouTube Channel

Thank You reading and watching; How to sew leather with a sewing machine Leathercraft Tutorial

Leather Sewing Machine Tutorial

Join Bruce Cheaney from the Cheaney Saddles YouTube channel as he takes you on a creative journey of sewing leather. In this short and to-the-point video, Bruce showcases the leather sewing machine and reveals the perfect thread and needle sizes for your saddle making projects. Get ready to dive into the world of sewing leather with expert guidance.

Learn how to sew saddle leather using a high-quality leather sewing machine.

Discover the essential techniques and tools needed to stitch leather with precision and durability. Master the art of leather sewing and take your cowboy machine skills to the next level.

Join us for a detailed and technical tutorial that will equip both beginners and experienced leather enthusiasts with the knowledge to create professional-grade leather products. Don’t miss out on this informative video that will revolutionize your leather sewing game.

Leather Sewing Machine always check your bobbin before you start sewing

Learn the art of sewing saddle leather with a high-performance leather sewing machine. Our detailed guide dives into the world of leathercraft, focusing on the versatile leather sewing machine.

Discover the techniques, tools, and tips required to achieve professional-quality stitching on cowboy saddles.

Whether you’re a seasoned leatherworker or a curious beginner, this video sheds light on the mechanics and intricacies of the leather sewing machine, empowering you to create durable and stunning leather goods.

Unleash your creativity while mastering the art of leather sewing with our comprehensive tutorial. Get ready to saddle up and sew with confidence using the power of a leather sewing machine.

Heavy duty leather sewing machine

Heavy duty leather sewing machine article and video by Bruce Cheaney

Sewing leather parts to a custom made saddle in this video I am sewing the center piece to the breast collar. The leather I am sewing is saddle skirting on top and burgundy latigo on the bottom side. The sewing machine thread is white polyester size 346 on top and bottom.

I use Schmetz needles size 230 for thick leather like the saddle parts I am sewing in this leather sewing tutorial.

Heavy duty leather sewing machine

Sewing single ply leather belts I use a Schmetz size 200 needle and white polyester 346 thread.

Leather sewing machine sew single ply leather belts to thick leather saddle parts Cowboy CB-4500 works great saddle making leather working leathercraft

How to sharpen leather tools. Leathercraft tutorials by Bruce. Best way to sharpen your leather edgers quickly and easily using this method. The leather edging tools in the video are made by C.S. Osborne and Company, Weaver Leather Supply and Barry King Leather Tools.

To find hand files, polishing, buffing, knife sharpening supplies try Jantz knife making supply. Jantz is where I get my Buffing, polishing and grinding supplies.

Thanks for watching I would appreciate a thumbs up.

You are welcome to subscribe to my YouTube channel. Bruce Cheaney Leathercraft.

How to sharpen leather tools – How to sharpen leather edge beveler

To find the Brownells 555 Black compound for polishing steel go to Brownells Gunsmith and Supplies and type in 555 in the search and you will locate the polishing compound I recommend.

Leathercraft Article and How to Video by Bruce Cheaney

Leather Wallet Making

Leather supply review patterns for making handmade leather wallets

Leather and patterns for making your own leather wallets. First of all I start by designing my own wallet patterns using heavy poster board, pencil, rule, small square and Berol circle template.

The next step is to select leather for making my wallets and I go to Tandy Leather for my vegetable tanned leather selection most of the time I place my order over the phone which works really well for me.

The leathers reviewed in this video are Oak-Leaf double shoulders numbers 9048-12 run 4 to 5 ounce and number 9050-12 runs 6 to 7 ounce in weight both of these double shoulders.

Next the side of vegetable tanned leather you see in the video that was on the bottom is Oak-Leaf side number 9157-56 (6-7 ounce) which is another very good choice for a slightly heavier wallet.

Sewing handmade leather wallet on a leather sewing machine

You can easily sew you leather wallet by hand using needle and thread and this will really look good as well as custom made. This video shows how I sew a leather wallet on a heavy duty harness stitcher sewing machine.

The sewing machine thread I am using is white polyester size 346 and the needle in the machine is made by Schmetz made in Germany and is is size 200. If you would like to use a smaller size thread you might consider size 207 and a size 180 Schmetz needle.

The Cowboy CB4500 has a Servo motor which enables you to sew at the speed that is comfortable for you.

Trimming the leather wallet with a Craftsman trim knife

Now I continue to make my handmade wallet by trimming the excess off of the bottom side. I am using a craftsman trimming knife and there are several places you can purchase a leather knife like this and I will list the contact information down below.

A leather knife like this is very handy for leathercraft and leather working some of the features are the brass blade keeper and a walnut handle and you can easily change the blades. I find that the curved blades have more cutting power and more effective than the straight blades.

When you are trimming the excess off hold you blade as straight as you can so the piece will not be angled or undercut.

Leathercraft Site Bruce Cheaney YouTube Channel

How to finish leather edges

Article and Video by Bruce Cheaney

How to finish leather edges. Burnishing leather with one of the best leather products I have ever used. Learn how to quickly and easily make your leathercraft and leather working projects look professional and beautiful.The product name is Wyo Quik Slik from Barry King Tools.

How to finish leather edges with Wyo Quik Slik

Additional YouTube video footage of me using Wyo Quik Slik for finishing and burnishing leather.

Burnishing and finishing leather with Wyo quik slik is easy and works great. I have tried and used this product on all kinds of leather vegetable tanned and even chrome tan leather which is the hardest leather to get a smooth edge on. I find that putting two coats of Wyo Quik Slick on the edge of burgundy latigo chrome tanned leather works real good and makes the edge of the leather very smooth and finished.

Leathercraft Site